Harrison/Frigidaire A6 air conditioning compressor

Welcome to the part two of this guide.

Now we're going to put our compressor together again, and let's start with the inside by just doing everyting backwards. But first it's a good idea to clean the shaft hole with some compressed air, to make sure dirt won't destroy the shaft seal later.

Insert one of the really big o-rings all the way in the case. Now try to insert the front valve plate with its valve metal sheet without having the o-ring falling out. This was a tricky part, I did it with the case horisontally, and i put a small amount of grease on the o-ring to make it sticky.

Now insert the main compressor content with its pistons and cylinders. Then install the oil pickup tube again.

Then it's time for the rear valve plate with its valve metal sheet, and then the oil pump.

Then insert the other big o-ring, followed by the rear head. It required some patience to make the oil pump fit in it.

<

Put on the fout big nuts and tighten them enough. (I don't know much "enough" is, I just know it must be "enough". Haha)

Now let's attack the other end by installing the shaft seal. This operation requires clean hands and a clean environment. You also need a little of the new refrigerant oil.

The sealing.

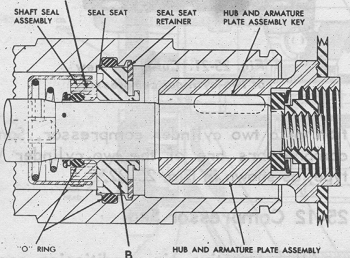

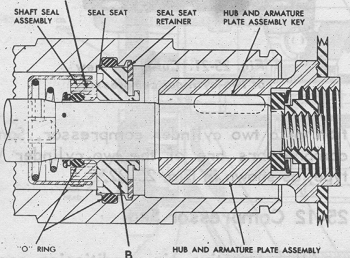

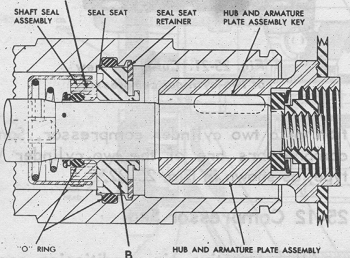

Look at this picture. It may be black and white, but it says more than a thousand words.

Lubricate the outer o-ring with refrigerant oil and install it in its groove.

Also lubricate the part of the sealing that contains a spring , and install it as the picture shows. The instructions to the seal kit says to NOT touch the sealing surface with your fingers.

Now install the other white ceramic part of the sealing. Lubricate that one too (keep the fingers away), and push it gently down the hole over the shaft, followed by the steel seat retainer that will hold it in place.

Once there, the only thing remaining is the pulley head. But first check the ball bearing if it's worn. I bought a new one for about $40.

Pulley head.

Install the pulley head, and don't forget the shaft key. Myself I used a rubber mallet. Don't hammer it to far, there must be space for the clutch to operate. 0.022-0.057 in says the specs. (0,55 - 1,44 mm).

Then install the shaft washer (and snap ring if any) and then the shaft nut. Be gently while turning the nut so the clutch gap won't change.

Tada! Now we're finished! Now you are local hero , who have saved a lot of money by doing this, and hopefully you have learned someting on the way. I did. ;o)

And don't forget the kids.. they're freezing.

(And also don't forget there's currently no oil in the compressor)

Mail me, Peter , if you have any comments or complains.

If you want to donate some money, cars or small plastic elephants, you're most welcome. :o) :o)

Back